Page 54 - Ratti_bilancio di sostenibilità_2021_en

P. 54

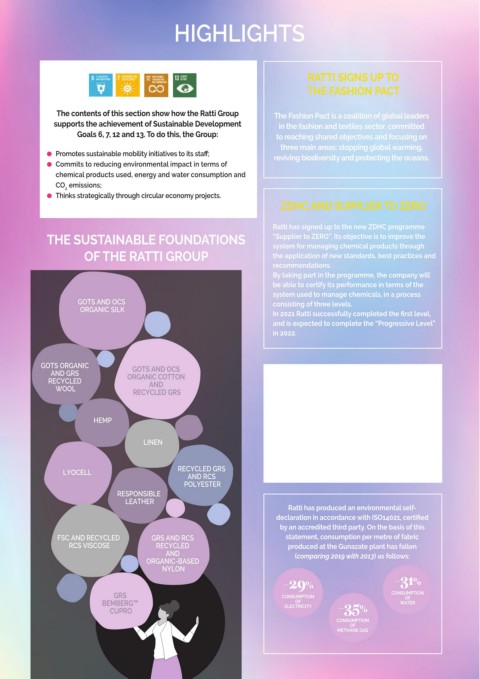

HIGHLIGHTS

RATTI SIGNS UP TO

THE FASHION PACT

The contents of this section show how the Ratti Group The Fashion Pact is a coalition of global leaders

supports the achievement of Sustainable Development in the fashion and textiles sector, committed

Goals 6, 7, 12 and 13. To do this, the Group: to reaching shared objectives and focusing on

three main areas: stopping global warming,

▪l Promotes sustainable mobility initiatives to its staff; reviving biodiversity and protecting the oceans.

l Commits to reducing environmental impact in terms of

chemical products used, energy and water consumption and

CO emissions;▪

2

l Thinks strategically through circular economy projects.

ZDHC AND SUPPLIER TO ZERO

Ratti has signed up to the new ZDHC programme

THE SUSTAINABLE FOUNDATIONS “Supplier to ZERO”. Its objective is to improve the

system for managing chemical products through

OF THE RATTI GROUP the application of new standards, best practices and

recommendations.

By taking part in the programme, the company will

be able to certify its performance in terms of the

system used to manage chemicals, in a process

GOTS AND OCS consisting of three levels.

ORGANIC SILK

In 2021 Ratti successfully completed the first level,

and is expected to complete the “Progressive Level”

in 2022.

GOTS ORGANIC GOTS AND OCS

AND GRS

RECYCLED ORGANIC COTTON RATTI DETERMINES

AND

WOOL

RECYCLED GRS ENVIRONMENTAL FOOTPRINT

THROUGH OEF

HEMP

Ratti SpA has decided to ascertain the environmental

footprint of its Guanzate plant by applying

LINEN

the OEF (Organisation Environmental Footprint)

methodology, a European standard which operates

LYOCELL RECYCLED GRS from the point of view of life cycle.

AND RCS

POLYESTER

RESPONSIBLE

LEATHER

Ratti has produced an environmental self-

declaration in accordance with ISO14021, certified

by an accredited third party. On the basis of this

FSC AND RECYCLED GRS AND RCS statement, consumption per metre of fabric

RCS VISCOSE RECYCLED produced at the Gunazate plant has fallen

AND (comparing 2019 with 2013) as follows:

ORGANIC-BASED

NYLON

–29% –31%

GRS CONSUMPTION CONSUMPTION

OF

BEMBERG™ ELECTRICITY WATER

OF

CUPRO –35%

CONSUMPTION

OF

METHANE GAS